Projects

Chlorination skid at Key West –

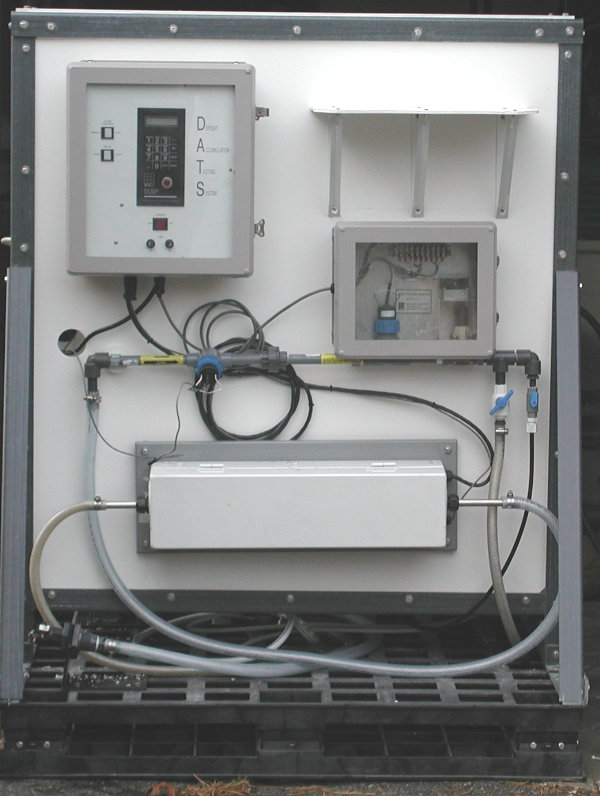

This skid was used to test the operation of our ProDATS sidestream fouling

monitor in a seawater environment. The US Navy lab in Key West is an ideal

site (for fouling and other things) as the weather is warm year round

and fouling continues unabated.

Chlorination skid at key west 2

Biofouling coating test – this

is an image of some test panels exposed at the intake of a power plant

for 1 year. Note the coverage of various organisms on the surface of the

12 x 12 inch panels. Some of these panels were controls (uncoated) and

some were coated with various nontoxic compounds intended to inhibit biological

fouling. Minor benefits, if any, can be attributed to the coatings. Score

1 for nature, 0 for coatings!

Chlor skid 2 front quarter – this is a custom rig under construction that will be used with a PC based data acquistion system in the upper enclosure. The fluid handling and valves will be used to take a side stream of cooling water through an industrial process as a prototype demonstration and software development platform.

Cooling water skid.pdf – this is a generic description of the typical cooling water test skids we have built and the equipment which we can install.

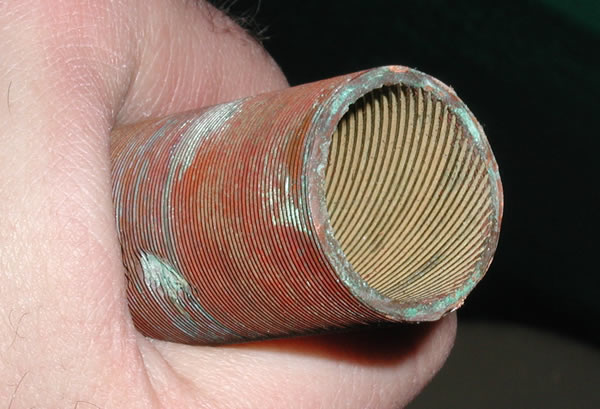

Fluted tube HVAC – close up image of common tube design in large chillers – flutes enhance heat transfer but complicate cleaning and exacerbate fouling problems (more sensitive to fouling, often fouls more quickly and is more difficult to restore to clean condition).

Macro fouling pipe end – even in a high velocity region numerous organisms from the ocean can settle and grow on inert surfaces. This pipe was exposed to seawater for 3 months of the summer and treated periodically with sodium hypochlorite (.2 ppm residual, 2 hours/day). Many of the simple aquatic life forms are biologically very rugged, whereas the complex life we desire (game fish) are more sensitive.

Macrofouling flow through test trailer

– this is a rear view of a simple trailer used to test the efficacy

of various cooling water treatment schedules and concentrations on site.

Macrofoulign trailer at site – the discharge end of a typical trailer

on site

ProDATS sidestream core – this is an early prototype of the instrumented core of the ProDATS side stream configuration. Through the translucent elements you can see the tube sections and heaters.

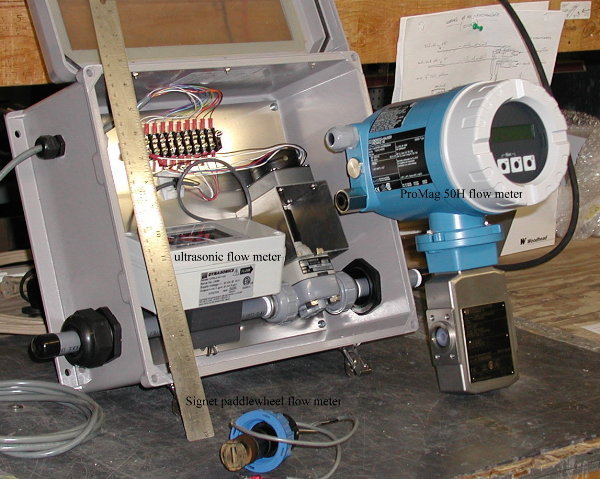

Promag 50H flow control – we customize our standard flow controller with whatever flow sensor a client desires. Here you see a ultrasonic type flow meter in the box and a magnetic type flow meter outside the box for relative size comparison. As the ProMag 50 was so large we were forced to mount the instrument outside the standard flow controller enclosure.

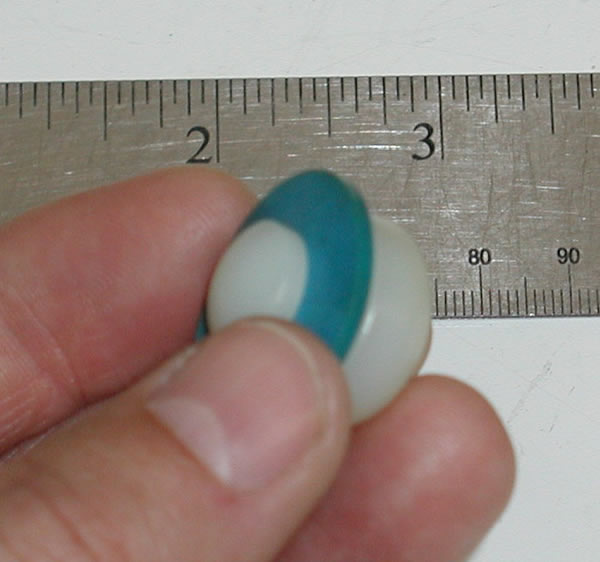

Sid tech supported by GE Betz – This is an image of a Sid-Tech “rocket” picked up on the beach in Prudence Island Narragansett Bay. The device is neutrally buoyant and is placed into the cooling water stream ahead of the power plant condenser. The water flow carries the device to the tube sheet where it self orients and passes through the tubes at random scraping them clean as it passes. After passing through the heat exchanger they are (supposed to be) collected and recirculated or stored for future use. As this technology is non-chemical, it can save the environment from exposure to a lot of biocide. Is the annoyance of seeing little white corks occasionally show up on the beach worth avoiding the unseen but likely more detrimental hypochlorite emissions?

DATS 2 mounted on skid – This is a typical layout for a DATS 2 mounted on a skid and ready to go to a power plant. They system is plumbed by the flexible lines underneath the system. The shelf is a place to rest the PC while communicating with the system. Notice both ends of the heat exchanger are accessible so the tube can be easily cleaned (with a rod) and/or removed for destructive inspection or replacement.

Taprogge abrasive ball 2 – This is a typical abrasive ball used by the Taprogge system to clean heat exchanger and condenser tubes on line. This company has been around since the 1950’s and has a presence all over the world. The balls are introduced ahead of the heat exchanger and collected after the heat exchanger for recirculation. They have an extensive line of automated equipment to control and operate this system. Sponge balls and abrasive (shown) balls in various sizes are available to take off soft or hard fouling in heat exchanger tubes.